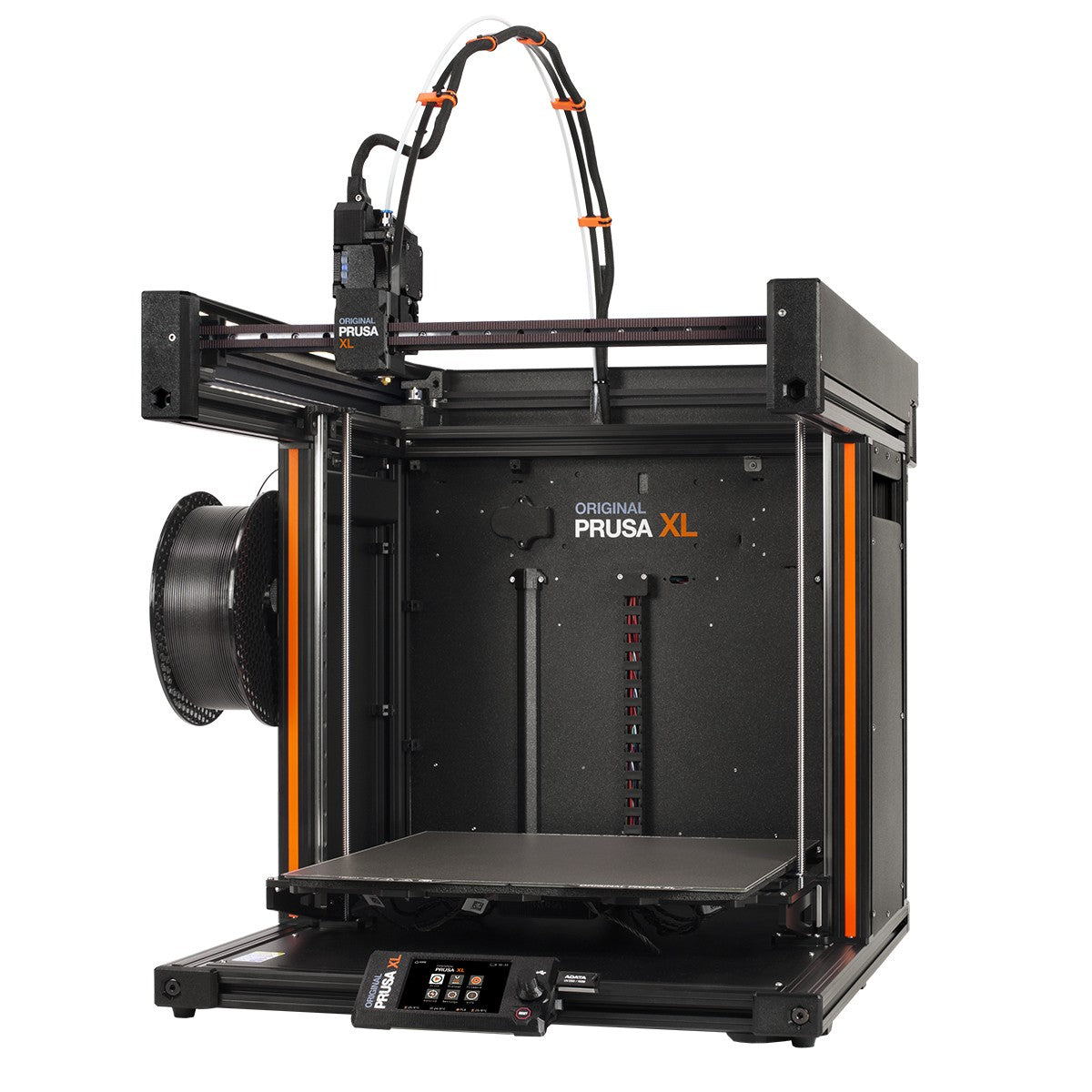

Original Prusa XL Semi Assembled 3D printer

Shop with Confidence at Printed Solid - No surprise Tariffs or Duties at Checkout!

Why our prices differ from Prusa

We have already paid the customs, duties, tariffs.

Shipping is already included on all orders greater that $50.00.

Compatible Accessories

GO BIG WITH THE ORIGINAL PRUSA XL!

The XL comes with the brand new “Nextruder”, a completely redesigned extruder with a planetary gearbox, hot-swappable nozzles and a Load Cell-based system for fully automatic first layer calibration. No manual calibration, no Live Z adjustments. The XL achieves a perfect first layer across the entire surface every time you start a print.

The print quality is further enhanced by the XL’s modular bed design - instead of using a single large heatbed, which is prone to warping, the XL uses an array of smaller, individually-controlled segments. Only the necessary part of the heatbed is activated when printing smaller objects, making the XL energy-efficient. Just like other Original Prusa 3D printers, the XL also uses proven double-sided spring steel sheets with various types of surfaces, allowing for easy maintenance and effortless print removal.

And perhaps the best feature: the XL can be easily expanded to up to five tool heads thanks to a highly accurate tool changer with automatic calibration via the load cell sensor - no more tedious calibration prints! Our internally developed kinematic coupler mechanism ensures millions of trouble-free tool changes. Using multiple tool heads opens up new options for your 3D printer: easily print soluble supports, print with up to five colors, or print with vastly different materials. The tool heads will be available individually in our e-shop as optional upgrades - so you can start with a single-extruder XL and upgrade it gradually over time based on your needs. More information about our plans for the tool changer and the benefits of various nozzle sizes can be found in our blog article.

With eight times larger print volume compared to the MINI+, no project is too big for the XL!

Articles

November 18. 2021 — Read more about the XL in the announcement article!

March 16. 2022 — Check out the Original Prusa XL Dev Diary #1 and FAQ

August 5. 2022 — XL Development Update: Reworked Nextruder, new features and updated shipping information

January 25. 2023 — XL Video Update: beta test news, hardware changes and shipping schedule

March 13. 2023 — Original Prusa XL update: shipping of first units starts, last minute improvements and FAQs

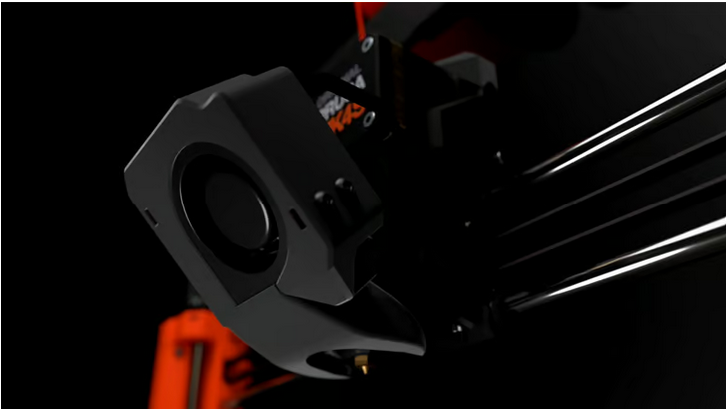

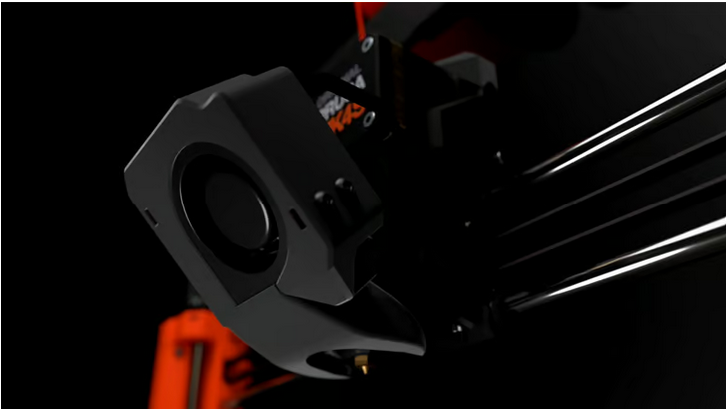

Introducing the Nextruder!

Say goodbye to Live Adjust Z!

When designing the XL, we left no stone unturned. The Nextruder is the new generation of 3D printer extruders. With built-in electronics, featuring a dedicated CPU and stepper driver directly in the print head, the Nextruder is controlled through a single-connector cable for easier maintenance. Fans, thermistors, the heater block and extruder motor - this all connects directly to the board inside the print head.

The completely redesigned extruder assembly allowed us to implement a fully automatic first layer calibration for an always-perfect first layer. Thanks to the internally-developed load cell sensor embedded within the heatsink, the XL can measure physical load in the heatsink and use the nozzle to probe the print surface. This way, the XL can utilize the load cell system to perform an incredibly precise height calculation for the first layer. No matter whether you just swapped the nozzle or the print sheet, there's no need to recalibrate anything. No Live Z, no manual adjustments. The XL delivers a perfectly smooth first layer every time you start a new print. The load cell sensor can do more, though! You can find more details in our blog post!

Filaments are no longer pushed by two small gears. Instead, we’re introducing a brand new planetary gearbox (1:10 ratio) with a large no-slip drive gear. This enables a higher level of control and also improves the compatibility with flexible materials. And there’s more: the nozzle and hotend are hot-swappable. The XL allows you to pull the entire brand new hotend assembly out of the extruder without the need to disassemble it. We've also added another thermistor into the heatbreak, which allows us to adjust the temperature according to the material specs and also detect heat creep.

What we are proud of

Nextruder

Built from the ground up, the Nextruder is a brand new extruder for Original Prusa 3D printers. Significantly lighter and packed with the latest technologies, including a minimal-backlash gearbox and no-slip drive gear, the Nextruder is designed to deliver top-notch performance and amazing-looking 3D prints.

Rigid CoreXY build

The XL is built around a sturdy aluminum extrusion frame, which makes the XL stable and rigid. Thanks to high-quality stepper motors, linear rails, and energy-efficient heatbed with 16 individually controlled segments, the XL delivers great-looking 3D prints up to 36×36×36 cm (14.17’’×14.17’’×14.17’’).

Power-loss recovery

Large prints can easily take days to finish. However, you don’t need to worry about power outages. The XL features hardware-based power-loss recovery. In case of a power failure, the XL stores the last known extruder location, so when the power is restored, the machine can pick up exactly where it left off.

Automatic First Layer Calibration

The Nextruder is equipped with the Load Cell function, which enables a fully-automatic first layer calibration without ANY user intervention. No adjustments, no tuning. Before every print, the XL measures the distance between the nozzle and the sheet with pinpoint accuracy, so it delivers a perfect first layer every single time.

Slice with PrusaSlicer!

Our internally developed multiplatform slicer comes with in-house made and fully tested profiles for all of our 3D printers and a wide range of filaments. With built-in tools, such as advanced support generation, cutting, automated object distribution, ironing and many others, you will turn your 3D models into print files in no time!

32bit electronics and smart features

The XL is powered by a new 32-bit motherboard with an expansion port, allowing an easy upgrade to up to five tool heads. Featuring popular enhancements, such as one-click-printing and G-code preview, the XL is easy to configure and operate.

Wide range of supported materials

The XL is fully compatible with a wide range of various types of materials. No matter whether you want to print something for fun from PLA and flexible materials, or you need to produce durable prototypes from PETG, ASA, Polycarbonate and Polypropylene - the XL can handle them all with ease.

Toolchanger

The XL can be upgraded with up to 5 individual print heads, each driven by its own electronics board. The internally developed toolchanger uses a reliable wear-resistant system and fully automatic tool alignment calibration ensuring millions of trouble-free tool swaps. This makes printing with multiple colors and with soluble supports quick and easy.

Features

- Printer design: Core XY

- Build volume: 360×360×360 mm (14.17’’×14.17’’×14.17’’)

- Printer dimensions: 800×800×900* mm (31.49’’ ×31.49’’× 35.43’’)* including side spoolholders and top enclosure cover (separate future add-on)

- Filament diameter: 1.75mm, wide range of thermoplastics supported (including, but not limited to PLA, PETG, ASA, ABS…)

- Extruder: Planetary 1:10 gearbox with no-slip drive gear, Load Cell sensor

- Tool Changer with up to 5 tool heads (optional upgrade via built-in expansion port)

- Bed: Segmented heatbed with 16 individually controlled segments

- Print surface: Removable magnetic steel sheets with different surface finishes

- Electronics: 32-bit custom-made board with an expansion slot, single-cable communication with tool heads, network features, one-click printing

- Mesh Bed Levelling: Load Cell-based fully automatic first layer calibration with no Live Z adjustment

- Power panic: Hardware-based, single G-Code line accuracy

- Ethernet connection: built-in

All information provided on this webpage are based on the current development stage of the XL and are subject to change.

Frequently asked questions

What is the return policy?

Our goal is for every customer to be totally satisfied with their purchase. If this isn’t the case, let us know and we’ll do our best to work with you to make it right.

Are any purchases final sale?

We are unable to accept returns on certain items. These will be carefully marked before purchase.

When will I get my order?

We will work quickly to ship your order as soon as possible. Once your order has shipped, you will receive an email with further information. Delivery times vary depending on your location.

Where are your products manufactured?

Our products are manufactured both locally and globally. We carefully select our manufacturing partners to ensure our products are high quality and a fair value.

How much does shipping cost?

Shipping is calculated based on your location and the items in your order. You will always know the shipping price before you purchase.