Robust Steel Exoskeleton

A design that works and looks the Part

Prusa CORE One is built as an all-steel exoskeleton. The enclosure is an integral part of the printer, providing it with outstanding stability and rigidity. However, maintenance is still simple, and if you need to replace a worn part in a couple of years, it’s a complete no-brainer. You can take everything apart with a screwdriver. As usual with us, we hold parts in stock for years

All-in-One Package

Get the Best Performance Right out of the Box

The CORE One L is equipped with an accelerometer, and the firmware comes with a built-in wizard for setting optimal belt tension. The printer comes pre-calibrated from the factory, but in case you want to ensure you’re getting a 100% performance after carrying out a larger maintenance, you can always recalibrate everything easily from the menu. The printer comes with two nozzles (high-flow and abrasive-resistant) to cover every filament.

Optimized for Print Farms and Industrial Applications

Boost your production with Prusa CORE One L!

We run a massive print farm with over 600 of our 3D printers producing parts for new 3D printers, so we know what it takes to run such a massive operation. And sometimes, you also need to print massive objects. The CORE One L offers the lowest downtime ratio compared to the MK4S and CORE One.

No Walled Garden or Vendor Locks

You own your printer, not just a license to use it

In the times of live service games, remote kill switches, and reliance on cloud servers, we’re staying true to our roots: you own your 3D printer, and you can use it for as long as you want, the way you want. It does not require any user account or internet access, so it can keep going forever.

Designed for Offline Use

100% Privacy: Offline Mode without Compromise

You don’t have to connect the CORE One L to the network - not even once. And you can still enjoy the full experience without any drawbacks. The printer can be configured and operated offline, including slicing and installation of firmware updates. The Wi-Fi module can be easily unplugged for environments with the highest level of security. Simply release a single screw on the back of the printer and pull the Wi-Fi module out.

Top security industries, highest-clearance manufacturing, companies working with sensitive data, government agencies, and many others will appreciate the comfort of knowing that the printer will not share a single byte of data with any cloud infrastructure, and still deliver the best possible performance.

We now also offer a special bundle for Critical Infrastructure. It’s the same performance as the CORE One L; however, its mainboard has no Wi-Fi circuitry at all, the printer comes without the camera, and there is a certified, encrypted USB drive in the package.

Built on a Strong Foundation

The CORE One L is a larger sibling of the Prusa CORE One, which marked a significant leap forward in the CoreXY market. TechRadar calls it “by far the most advanced and functional printer of this type on the market at present.” Recognized for its excellent build and professional-grade features, it delivers consistently reliable performance with top speed, accuracy, and versatility - earning it the title of “Best Enclosed 3D Printer of 2025” by All3DP. With a Red Dot Award to its name, it also proves that functionality can go hand-in-hand with standout design.

Create colorful 3D objects!

The CORE One L is compatible with the MMU3, the add-on for the fastest single-nozzle printing with up to five filaments at the same time. You can create beautiful, colorful objects, and you won’t have to throw half of your filaments away or constantly clean the surroundings of your printer. Our solution uses an innovative retraction technique and a compact wipe tower to manage filament changes. This not only reduces the wasted filament but also deposits all the waste to a single, tidy block. MMU3 for the CORE One L will be released in early 2026.

Make it your own!

The printer comes assembled and pre-calibrated from the factory, so you don’t have to do anything to get the best performance out of the box. However, you are completely free to customize your printer to your liking. No parts of the printer are glued together, everything can be taken apart with a set of screwdrivers, and there’s plenty of room for mods, creativity, and customization - so go ahead and make the CORE One your own! Print magnetic holders, organizers, or just plain fun stuff to make your printer stand out.

Our software and firmware are open-source, and you can grab the source code at GitHub.com. This allows you to modify the code, and come up with your own modifications and tweaks. We often cooperate with our community members on new features, and you can become one of them!

Easy to Master

Our most approachable printer yet!

CORE One L is ready to print right after unpacking. It’s incredibly easy to start printing. To truly appreciate and explore all the aspects of your new printer, we’re including a comprehensive Prusa Academy course on the CORE One L at no extra cost with every machine. This is perfect for 3D printing newcomers, in the educational sector, but it also makes onboarding new employees a breeze.

Technical Parameters

| Measurements | |

|---|---|

| Build Volume | 300 x 300 x 330 mm | 11.8 x 11.8 x 12.99 in |

| Filament diameter | 1.75 mm |

| Layer height | 0.05-0.30 mm |

| Printer dimensions | 21,9 kg, 469×521×635 mm; 18.5×20.5×25 in (W×D×H) |

| Electronics | |

| Mainboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper Drivers | Trinamic 2130 |

| Stepper motors | Precise 0.9° X,Y stepper motors (prevents VFA) |

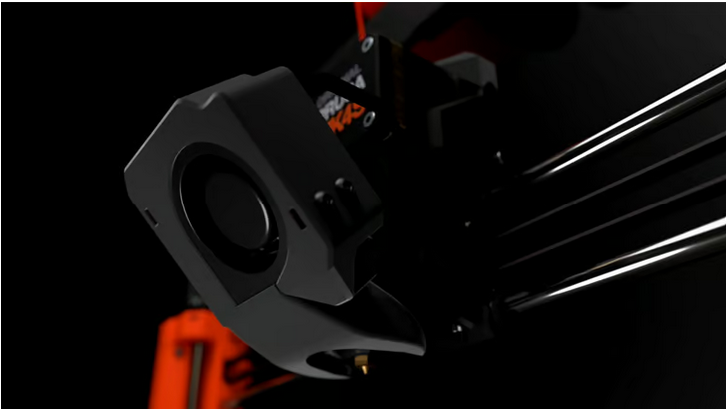

| Extruder | |

| Extruder | Nextruder, Direct Drive, E3D V6 compatible (with adapter) |

| Extruder electronics | Custom breakout board for connecting fans, thermistors and other parts. |

| Filament path | Aluminum heatsink, all-metal hotend |

| Drive system | Nextruder Planetary Gear System, 10:1 gearbox ratio |

| Cooling fan | High-performance turbine, 360° cooling system |

| Nozzle | High-flow Prusa Nozzle brass CHT - 0.4 mm + Abrasive-Resistant 0.4mm nozzle in the box |

| Max. operating temperature | |

| Max nozzle temperature | 290 °C / 554 °F |

| Max heatbed temperature | 120 °C / 248 °F |

| Max chamber temperature | 60 °C / 140 °F |

| Controls | |

| LCD screen | 3.5″ graphic 65k color screen |

| Touch control | Yes |

| Firmware update interface | USB drive, Prusa Connect, Prusa Mobile App |

| Prusa Connect support | Yes |

| Prusa App for iOS and Android support | Yes |

| Quick-Swap nozzle system | Yes |

| Lighting | Yes |

| Accessories | |

| Internal camera | Included in the box, installation optional |

| MMU3 support | Yes. MMU3 (available Jan 2026) |

| Advanced Filtration System | optional addon |

| GPIO Board compatibility | Yes |

| Accelerometer compatibility | Yes, built-in |

| Connectivity | |

| Ethernet connection | Yes |

| Other connectivity | NFC receiver |

| Sensors | |

| Filament Sensor | Yes (2 sensors) |

| Loadcell sensor | Yes |

| Thermistors | 5 high-precision thermistors (genuine Semitec) |

| Fan motors monitoring | Yes |

| Door sensor | Yes |

| Printing | |

| Print medium | USB drive / LAN / internet via Prusa Connect or mobile Prusa App |

| Print surface | Magnetic heatbed with removable PEI spring steel sheets |

| First layer calibration | Fully automatic (thanks to the Load Cell sensor) |

| Bed calibration | Automatic, Mesh Bed Leveling (only on print area) |

| Input shaper | Yes |

| Supported materials | PLA, PETG, Flex, PVA, PC, PP, CPE, PVB and when using the optional Advanced Filtration System ABS, ASA, HIPS, PA |

| Phase Stepping | Yes |